Ukwethulwa kwezindlela ezinhlanu zokushisela i-laser plastic

Eminyakeni yamuva nje, ngokuthuthukiswa okuqhubekayo kobuchwepheshe, i-laser welding of plastics izokhombisa kancane kancane umkhuba okhulayo esikhathini esizayo.Eminyakeni embalwa edlule, obunye ubuchwepheshe be-laser abukaphuki, futhi intengo ye-laser iphezulu uma kuqhathaniswa.Uma kuqhathaniswa nokushisela okujwayelekile, ukutshalwa kwezimali kwesikhathi esisodwa kukhulu, okungenzeka kungakhiqizi izinzuzo ngokushesha.Kodwa manje inzuzo yezomnotho ye-laser igqanyisiwe.I-laser welding yepulasitiki inganciphisa ubunzima kubaklami ukuklama imikhiqizo.

Njengamanje, imikhiqizo eminingi (okubandakanya imboni yezimoto ze-semiconductor, imboni yezemithi nokudla, njll.) inezidingo eziphakeme kakhulu zokucubungula ukunemba nokubukeka kobuhle, okwenza i-laser welding ibe inqubo edingekayo yokukhiqiza le mikhiqizo futhi ikhuthaze ukuthuthuka okuqhubekayo ubuchwepheshe be-laser welding.

Uma kuseduze ukuhambisana, izinga lokushisa elihlanganisiwe kanye nokuhambisana kwe-plastic laser welding, umphumela wayo uzoba ngcono.Imodi yokufakwa kwe-plastic laser welding ihlukile kuleyo yokushisela insimbi, okuhlanganisa ukushisela okulandelanayo kwe-circumferential, i-quasi synchronous welding, i-synchronous welding kanye ne-irradiation mask welding.I-Olay Optoelectronics izokwethula kafushane lezi zindlela zokushisela.

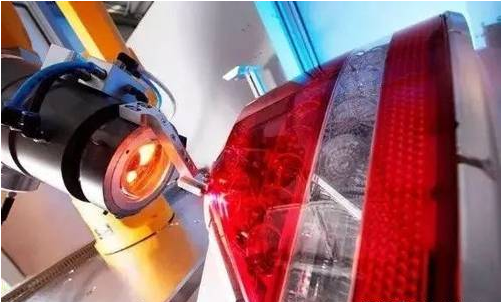

1. Profile Welding

I-laser ihamba ngomugqa wekhonta wesendlalelo sokushisela sepulasitiki bese siyincibilikisa ukuze kancane kancane ihlanganise izingqimba zepulasitiki;Noma hambisa isemishi ngomugqa we-laser ongashintshi ukuze ufeze inhloso yokushisela.

Ekusetshenzisweni okungokoqobo, i-contour welding inezidingo eziphezulu zekhwalithi yezingxenye ezibunjwe ngomjovo, ikakhulukazi ukusetshenziswa kwemigqa yokushisela eyinkimbinkimbi njengezihlukanisi zikawoyela negesi.Enkambweni ye-plastic laser welding, i-contour welding ingafinyelela ukungena okuthile komugqa wokushisela, kodwa lokhu kungena kuncane futhi akulawuleki, okudinga ukuthi ukuguqulwa kwezingxenye zokubumba umjovo akufanele kube kukhulu kakhulu.

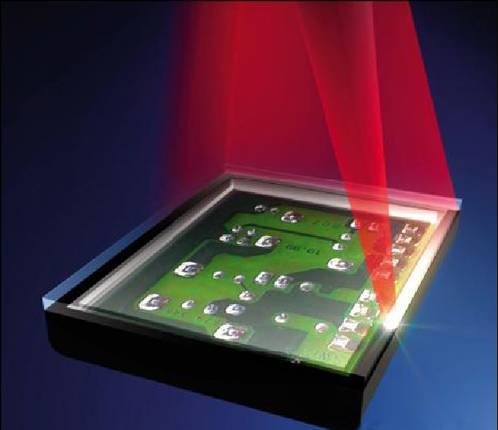

2. Ukushisela okuhambisanayo

I-laser beam evela kuma-laser diode amaningi akhiwe ngezinto ezibonakalayo.I-laser beam iqondiswa eduze komugqa wekhonta wesendlalelo sokushisela futhi ikhiqiza ukushisa kumthungo wokushisela, ukuze wonke umugqa wekhonta uyancibilike futhi uhlanganiswe ndawonye ngesikhathi esifanayo.

I-synchronous welding isetshenziswa kakhulu kumalambu ezimoto nasembonini yezokwelapha.I-synchronous welding iyi-multi beam, i-optical shape ibonisa indawo ekhanyayo yethrekhi yokushisela, ebonakala ngokunciphisa ukucindezeleka kwangaphakathi.Ngenxa yokuthi izidingo ziphakeme uma kuqhathaniswa futhi intengo iyonke iphakeme uma kuqhathaniswa, isetshenziswa kabanzi ekwelashweni.

3. Ukuskena ukushisela

I-Laser scanning welding diagram

I-scanning welding ibizwa nangokuthi i-quasi synchronous welding.Ubuchwepheshe be-welding wokuskena buhlanganisa ubuchwepheshe bokushisela obubili obungenhla, okungukuthi, ukushisela okulandelanayo okujikelezayo kanye ne-synchronous welding.I-reflector isetshenziselwa ukukhiqiza i-laser beam enesivinini esikhulu enesivinini esingu-10 m/s, ehamba eduze kwengxenye ezoshiselwa, okwenza yonke ingxenye yokushisela ifudumale kancane kancane futhi ihlangane ndawonye.

I-Quasi synchronous welding isetshenziswa kabanzi.Embonini yezingxenye zezimoto, isebenzisa i-XY high-frequency galvanometer ngaphakathi.Umongo wayo ukulawula ukuwa kwe-plastic welding yezinto ezimbili.I-Contour welding izokhiqiza ukucindezeleka okukhulu kwangaphakathi, okuzothinta ukubekwa uphawu kwezinto.Ukuvumelanisa kwe-Quasi kuyimodi yokuskena ngesivinini esikhulu, futhi ngokulawula kwamanje, kungaqeda ngempumelelo ukucindezeleka kwangaphakathi.

4. Rolling welding

Umfanekiso we-laser rolling welding

I-Rolling Welding iyinqubo yokushisela ye-laser plastic, enezinhlobo eziningi ezahlukene.Kunezinhlobo ezimbili eziyinhloko ze-rolling welding:

Eyokuqala i-Globo ball welding.Kunebhola lengilazi le-air cushion ekugcineni kwelensi ye-laser, engagxilisa i-laser futhi ibambe izingxenye zepulasitiki.Enqubweni yokushisela, i-Globo lens iqhutshwa isiteji sokunyakaza ukuze iqedele ukushisela ngokugingqa eduze komugqa wokushisela.Yonke le nqubo ilula njengokubhala ngepeni lokukhomba.Inqubo yokushisela i-globo ayidingi into engaphezulu eyinkimbinkimbi, kodwa kuphela umkhiqizo osekela isikhunta esiphansi.Inqubo yokushisela ibhola ye-Globo nayo inenqubo yokushisela i-roller roller ehlukile.Umehluko wukuthi ibhola lengilazi elisekupheleni kwelensi liguqulwa libe umphongolo wengilazi oyicylindrical ukuze kutholwe ingxenye yelaser ebanzi.I-roller roller welding ifaneleka ukushisela okubanzi.

Eyesibili inqubo yokushisela i-TwinWeld.Le nqubo ye-plastic laser welding yengeza i-roller yensimbi ekupheleni kwelensi.Ngesikhathi senqubo yokushisela, i-roller icindezela umkhawulo we-welding welding.Inzuzo yale nqubo ye-plastic laser welding yukuthi isondo lokucindezela insimbi ngeke ligqokwe, elivumela ukukhiqizwa okukhulu.Kodwa-ke, ukucindezela kwe-roller yokucindezela kusebenza emaphethelweni omugqa wokushisela, okulula ukukhiqiza i-torque futhi kwakha amaphutha ahlukahlukene we-welding.Ngesikhathi esifanayo, ngenxa yokuthi isakhiwo se-lens siyinkimbinkimbi, kunzima ukuhlelwa kwe-welding.

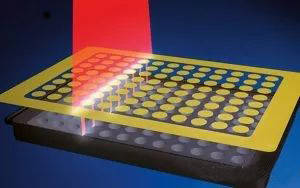

5. I-Irradiation mask welding

I-Laser irradiation mask welding diagram

I-laser beam ibekwe ngesifanekiso ukuze incibilike futhi ibophe ipulasitiki.Isifanekiso sidalula kuphela ingxenye encane yokushisela enembe ongqimbeni lwepulasitiki olungezansi.I-laser beam ishisa kuphela ingxenye yomkhiqizo engamboziwe imaski.Lobu buchwepheshe bungasetshenziswa ukuze kuzuzwe ukushisela okunembe kakhulu okuphansi njengama-microns ayi-10.

Izingxenye ze-microfluidic zingashiselwa ngokunembile nangokuzinzile ngomgomo wokushisela imaski.Ijiyomethri yesiteshi izohlala injalo, igwema ukuncibilika kumzila omncane ongu-200 µ m kuphela.

Isikhathi sokuthumela: Oct-21-2022