Ngo-May 2022, i-CCTV yabika ukuthi idatha yakamuva evela ku-National Energy Administration ibonisa ukuthi kusukela manje, amaphrojekthi okukhiqiza amandla e-photovoltaic asakhiwa angama-kilowatts ayizigidi ezingu-121, futhi kulindeleke ukuthi ukukhiqizwa kwamandla kagesi we-photovoltaic ngonyaka kuzoxhunywa kugridi. ngama-kilowatts ayizigidi eziyi-108, okuwukukhula ngo-95.9% kunonyaka odlule.

Ukwanda okuqhubekayo komthamo ofakiwe we-PV womhlaba wonke kusheshise ukusetshenziswa kobuchwepheshe bokucubungula i-laser embonini ye-photovoltaic.Ukuthuthukiswa okuqhubekayo kobuchwepheshe bokucubungula i-laser kubuye kwathuthukisa ukusebenza kahle kokusetshenziswa kwamandla e-photovoltaic.Ngokwezibalo ezifanele, imakethe ye-PV entsha efakiwe emhlabeni wonke isifinyelele ku-130GW ngo-2020, yephula umlando omusha.Ngenkathi umthamo womhlaba wonke ofakiwe we-PV usufinyelele ezingeni eliphezulu elisha, njengezwe elikhulu elikhiqiza yonke indawo, umthamo wokufakwa kwe-PV waseChina ubulokhu ugcina ukukhuphuka.Kusukela ngo-2010, ukukhishwa kwamaseli e-photovoltaic e-China kudlule i-50% yomkhiqizo ophelele womhlaba wonke, okuwumqondo wangempela.Ingxenye engaphezu kwengxenye yemboni ye-photovoltaic yomhlaba ikhiqizwa futhi ithunyelwa ngaphandle.

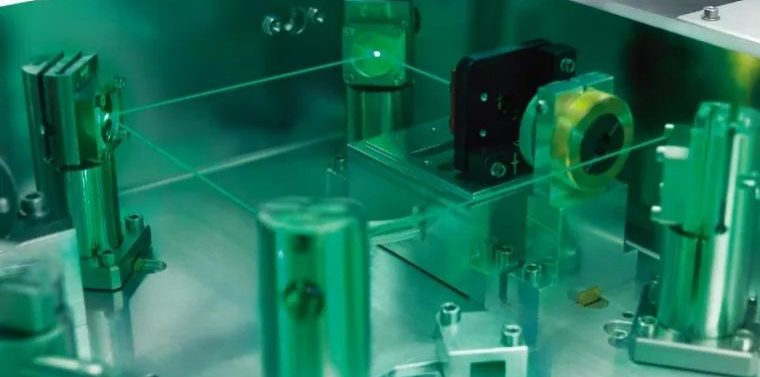

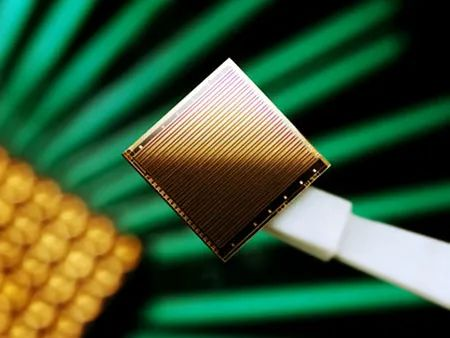

Njengethuluzi lezimboni, i-laser ubuchwepheshe obuyinhloko embonini ye-photovoltaic.I-Laser ingagxilisa inani elikhulu lamandla endaweni encane yesiphambano futhi iyikhulule, ithuthukise kakhulu ukusebenza kahle kokusetshenziswa kwamandla, ukuze ikwazi ukusika izinto eziqinile.Ukukhiqizwa kwebhethri kubaluleke kakhulu ekukhiqizeni i-photovoltaic.Amaseli e-silicon adlala indima ebalulekile ekukhiqizeni amandla e-photovoltaic, kungakhathaliseki ukuthi amangqamuzana e-silicon e-crystalline noma amaseli ama-silicon efilimu amancane.Kumaseli e-silicon e-crystalline, i-high-purity single crystal/polycrystal isikwa ibe amawafa e-silicon ukuze amabhethri, futhi i-laser isetshenziselwa ukusika, ukulolonga, nokubhalwa kangcono, bese kuxhunywa amaseli.

01 Ukwelashwa konqenqema lwebhethri

Isici esibalulekile sokuthuthukisa ukusebenza kahle kwamaseli elanga ukunciphisa ukulahleka kwamandla ngokufakwa kukagesi, imvamisa ngokuhlanganisa nokudlula imiphetho yama-silicon chips.Inqubo yendabuko isebenzisa i-plasma ukwelapha ukuvala onqenqemeni, kodwa amakhemikhali e-etching asetshenziswayo ayabiza futhi ayingozi endaweni ezungezile.I-Laser enamandla amakhulu namandla aphezulu ingadlula ngokushesha unqenqema lweseli futhi ivimbele ukulahlekelwa kwamandla amaningi.Nge-laser eyakhiwe i-groove, ukulahlekelwa kwamandla okubangelwa ukuvuza kwamanje kweseli yelanga kuncipha kakhulu, kusuka ku-10-15% wokulahlekelwa okubangelwa inqubo yokufaka amakhemikhali evamile kuya ku-2-3% wokulahlekelwa okubangelwa ubuchwepheshe be-laser. .

02 Hlela futhi Ubhale

Ukuhlela amawafa e-silicon nge-laser kuyinqubo evamile eku-inthanethi yochungechunge oluzenzakalelayo lokushisela amaseli elanga.Ukuxhuma amaseli elanga ngale ndlela kunciphisa izindleko zokugcina futhi kwenza izintambo zebhethri zemojuli ngayinye zihleleke futhi zihlangane.

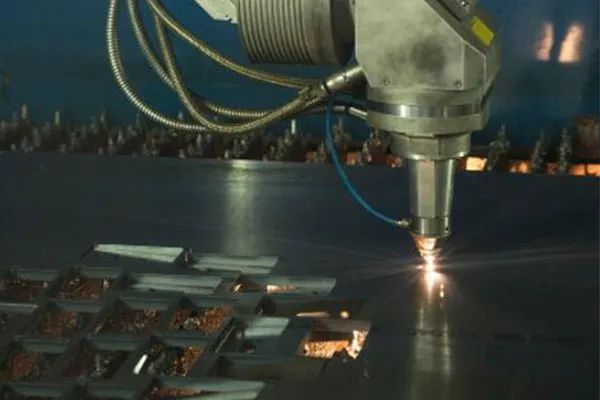

03 Ukusika nokubhala

Njengamanje, kuthuthuke kakhulu ukusebenzisa i-laser ukunwaya nokusika amawafa e-silicon.Inokusebenzisa ukunemba okuphezulu, ukunemba okuphezulu kokuphindaphinda, ukusebenza okuzinzile, isivinini esisheshayo, ukusebenza okulula nokugcinwa okulula.

04 I-Silicon wafer marking

Ukusetshenziswa okuphawulekayo kwe-laser embonini ye-silicon photovoltaic ukumaka i-silicon ngaphandle kokuphazamisa ukusebenza kwayo.Ukulebula nge-wafer kusiza abakhiqizi balandele uchungechunge lwabo lokuhlinzeka ngelanga futhi baqinisekise ikhwalithi ezinzile.

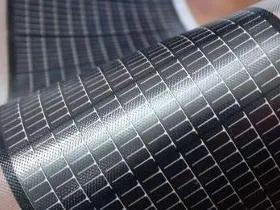

05 Ukukhishwa kwefilimu

Amaseli elanga anefilimu azacile ancike ekufakweni komhwamuko kanye nobuchwepheshe bokubhala ukuze ukhethe ngokukhetha izendlalelo ezithile ukuze kuzuzwe ukuhlukaniswa kukagesi.Ungqimba ngalunye lwefilimu ludinga ukufakwa ngokushesha ngaphandle kokuthinta ezinye izingqimba zengilazi ye-substrate ne-silicon.Ukukhipha ngokushesha umoya kuzoholela ekulimaleni kwesekethe engilazini nasezingqimbeni ze-silicon, okuzoholela ekuhlulekeni kwebhethri.

Ukuze kuqinisekiswe ukuzinza, ikhwalithi kanye nokufana kokusebenza kokuphehla amandla phakathi kwezingxenye, amandla e-laser beam kufanele alungiswe ngokucophelela ku-workshop yokukhiqiza.Uma amandla e-laser engakwazi ukufinyelela ezingeni elithile, inqubo yokubhala ayikwazi ukuqedwa.Ngokufanayo, i-beam kufanele igcine amandla ngaphakathi kwebanga elincane futhi iqinisekise isimo sokusebenza samahora angu-7 * 24 emgqeni womhlangano.Zonke lezi zici zibeka phambili izidingo eziqinile zokucaciswa kwe-laser, futhi imishini yokuqapha eyinkimbinkimbi kufanele isetshenziselwe ukuqinisekisa ukusebenza okuphezulu.

Abakhiqizi basebenzisa isilinganiso samandla ensimbi ukuze benze i-laser ngendlela oyifisayo futhi bayilungise ukuze ihlangabezane nezidingo zohlelo lokusebenza.Kuma-laser anamandla amakhulu, kunamathuluzi amaningi okulinganisa amandla ahlukene, futhi izitholi zamandla aphezulu zingaphula umkhawulo wama-lasers ngaphansi kwezimo ezikhethekile;Amalaza asetshenziswa ekusikeni ingilazi noma kwezinye izinhlelo zokusebenza zokubeka adinga ukunakwa ezicini ezinhle ze-beam, hhayi amandla.

Uma ifilimu elincanyana i-photovoltaic isetshenziselwa ukucisha izinto zikagesi, izici ze-boam zibaluleke kakhulu kunamandla okuqala.Usayizi, umumo namandla kudlala indima ebalulekile ekuvimbeleni ukuvuza kwamanje kwebhethri lemojuli.I-laser beam eshisa okokusebenza kwe-photovoltaic efakwe epuleti lengilazi eyisisekelo nayo idinga ukulungiswa kahle.Njengendawo yokuxhumana enhle yokukhiqiza amasekhethi ebhethri, ugongolo kufanele luhlangabezane nawo wonke amazinga.Imishayo yekhwalithi ephezulu kuphela enokuphindaphindwa okuphezulu engacisha kahle isekethe ngaphandle kokulimaza ingilazi engezansi.Kulokhu, umtshina we-thermoelectric okwazi ukukala amandla e-laser beam ngokuphindaphindiwe ngokuvamile uyadingeka.

Usayizi wesikhungo se-laser beam uzothinta imodi yayo yokukhipha kanye nendawo.Ukuzungeza (noma i-ovality) ye-beam kuzothinta umugqa wababhali ovezwe kumojula yelanga.Uma ukubhalwa kungalingani, i-ellipticity ye-beam engahambisani izodala amaphutha kumojula yelanga.Ukuma kwe-beam yonke kuthinta nokusebenza kwesakhiwo se-silicon doped.Kubacwaningi, kubalulekile ukukhetha i-laser enekhwalithi enhle, kungakhathaliseki ukuthi ijubane lokucubungula kanye nezindleko.Kodwa-ke, ekukhiqizeni, ama-laser akhiyiwe emodi ngokuvamile asetshenziselwa ama-pulses amafushane adingekayo ukuze ahwamuke ekukhiqizeni ibhethri.

Izinto ezintsha ezifana ne-perovskite zinikeza inqubo yokukhiqiza eshibhile futhi ehluke ngokuphelele kusuka kumabhethri e-silicon e-crystalline yendabuko.Enye yezinzuzo ezinkulu ze-perovskite ukuthi inganciphisa umthelela wokucubungula nokukhiqizwa kwe-crystalline silicon emvelweni ngenkathi igcina ukusebenza kahle.Njengamanje, ukufakwa komhwamuko kwezinto zayo kusebenzisa nobuchwepheshe bokucubungula i-laser.Ngakho-ke, embonini ye-photovoltaic, ubuchwepheshe be-laser busetshenziswa ngokuya ngenqubo ye-doping.Ama-lasers we-Photovoltaic asetshenziswa ezinqubweni ezihlukahlukene zokukhiqiza.Ekukhiqizeni amaseli elanga e-crystalline silicon, ubuchwepheshe be-laser busetshenziselwa ukusika ama-silicon chips kanye nokufakwa onqenqemeni.I-doping yonqenqema lwebhethri ukuvimbela ukujikeleza okufushane kwe-electrode yangaphambili ne-electrode yangemuva.Kulolu hlelo lokusebenza, ubuchwepheshe be-laser budlule ngokuphelele ezinye izinqubo zendabuko.Kukholakala ukuthi kuzoba nezinhlelo eziningi zokusebenza zobuchwepheshe be-laser kuyo yonke imboni ehlobene ne-photovoltaic esikhathini esizayo.

Isikhathi sokuthumela: Oct-14-2022