Kuyini ukungena kwe-welding?Kubhekiselwa ekujuleni kokuncibilika kwensimbi eyisisekelo noma ubuhlalu obuyi-weld obungaphambili engxenyeni yesiphambano sejoyinti elishiselwe.

Amajoyinti ashiselwe afaka: i-weld seam (0A), indawo yokuhlanganisa (AB) nendawo ethintekile ekushiseni (BC).

Isinyathelo 1: Isampula

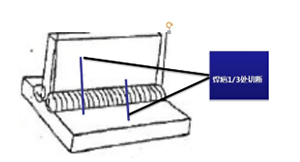

(1) Indawo yokusika yesampula yokungena yokushisela: a.Gwema ukuqala nokumisa izikhundla

b.Sika ku-1/3 yesibazi se-weld

c.Uma ubude besibazi sokushisela bungaphansi kuka-20mm, nqunywa phakathi nesibazi sokushisela.

(2) Ukusika

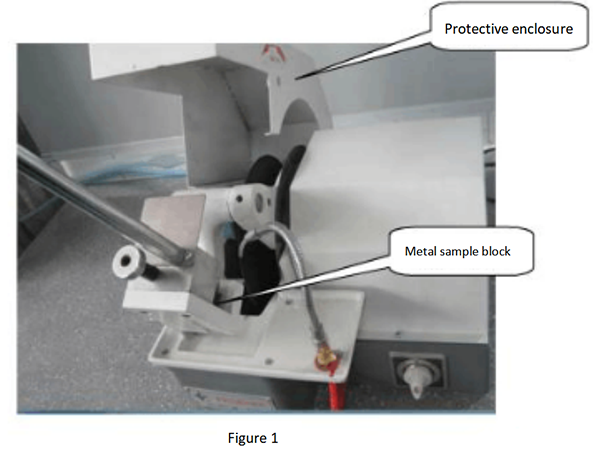

A. Xhuma ugesi futhi uhlole ukuthi okokukala kuyahlangabezana yini nezidingo zokuhlola;Njengoba kuboniswe kuMfanekiso 1, vula indlu yokuvikela yomshini wokusika i-metallographic bese ufaka ibhulokhi yesampula yensimbi ezohlolwa.

(Qaphela: Qiniseka ukuthi uyilungisa ngokuphelele insimbi!)

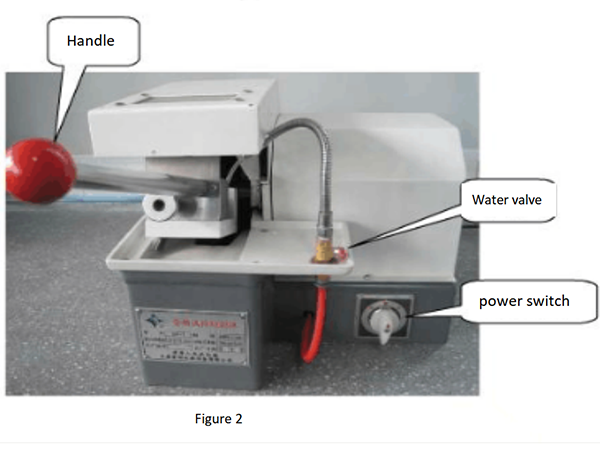

b.Njengoba kuboniswe kuMfanekiso 2, vala igobolondo elivikelayo lomshini wokusika i-metallographic, vula i-valve yamanzi, bese uvula inkinobho yamandla;Bamba isibambo somshini wokusika i-metallographic bese usicindezela kancane usike phansi ukuze usike isampula yensimbi.Ngemva kokusika, ubude, ububanzi nokuphakama kwesampula yensimbi kuyoba ngaphansi kuka-4mm;Vala i-valve yamanzi, vala amandla, bese ukhipha isampula yensimbi.

b.Njengoba kuboniswe kuMfanekiso 2, vala igobolondo elivikelayo lomshini wokusika i-metallographic, vula i-valve yamanzi, bese uvula inkinobho yamandla;Bamba isibambo somshini wokusika i-metallographic bese usicindezela kancane usike phansi ukuze usike isampula yensimbi.Ngemva kokusika, ubude, ububanzi nokuphakama kwesampula yensimbi kuyoba ngaphansi kuka-4mm;Vala i-valve yamanzi, vala amandla, bese ukhipha isampula yensimbi.

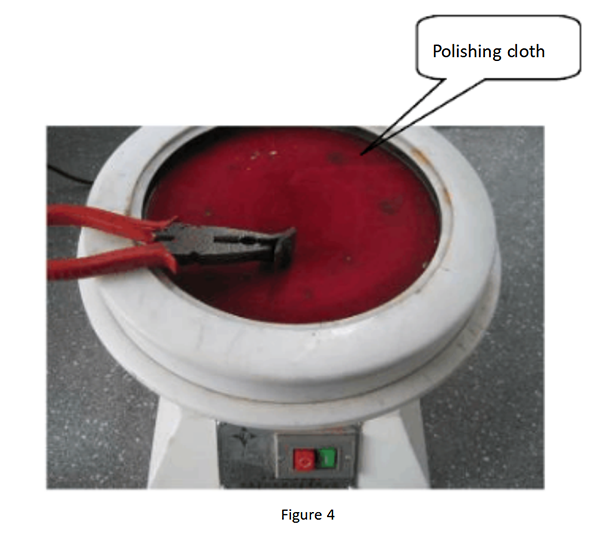

Isinyathelo sesi-3: Ukugqwala

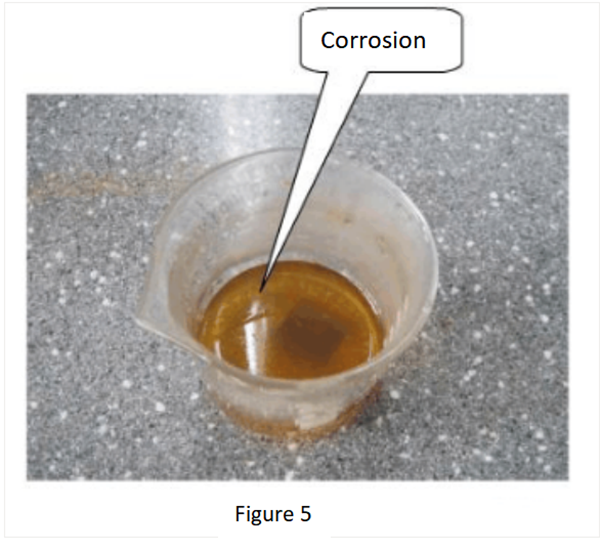

(1) Njengoba kuboniswe kumfanekiso wesi-5, sebenzisa utshwala obuphelele ne-nitric acid ukuze ulungise isixazululo sokugqwala (3-5% i-nitric acid notshwala) enkomishini yokulinganisa, faka isampula yensimbi kusixazululo sokugqwala noma usebenzise ibhulashi elincane ukugeza. indawo esikiwe yokugqwala.Isikhathi sokugqwala singamasekhondi ayi-10-15, futhi umphumela wokugqwala othize udinga ukubukwa ngokubonakalayo.

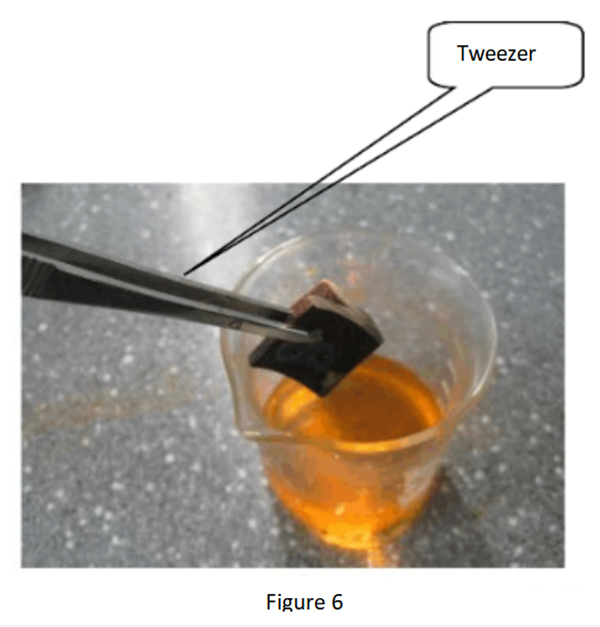

(2) Njengoba kubonisiwe kumfanekiso wesi-6, ngemva kokugqwala, khipha isampula yensimbi nge-tweezers (inothi: ungathinti uketshezi olugqwala ngezandla), bese uhlanza isixazululo sokugqwala endaweni yesampula yensimbi ngokuhlanzekile. amanzi.

(1) Vuthela zome

Isinyathelo sesi-4: Indlela yokuhlola yokungena kwe-welding

| I-T (mm) ubukhulu bepuleti | |||

| Ibhentshimakhi endala | Ibhentshimakhi entsha | ||

| Ukujiya kwepuleti | Idatha yokungena | Ukujiya kwepuleti | Idatha yokungena |

| ≤3.2 | Ngaphezulu kuka-0.2 * t | t≤4.0 | Ngaphezulu kuka-0.2 * t |

| 4.0<t≤4.5 | Ngaphezulu kuka-0.8 | ||

| 3.2~4.5 (Kufaka 4.5) | Ngaphezulu kuka-0.7 | 4.5<t≤8.0 | Ngaphezulu kuka-1.0 |

| t=9.0 | Ngaphezulu kuka-1.4 | ||

| >4.5 | Ngaphezulu kuka-1.0 | t≥12.0 | Ngaphezulu kuka-1.5 |

| Qaphela: Ukushisela kwepuleti elincane nepuleti eliwugqinsi kusekelwe epuletini elincanyana | |||

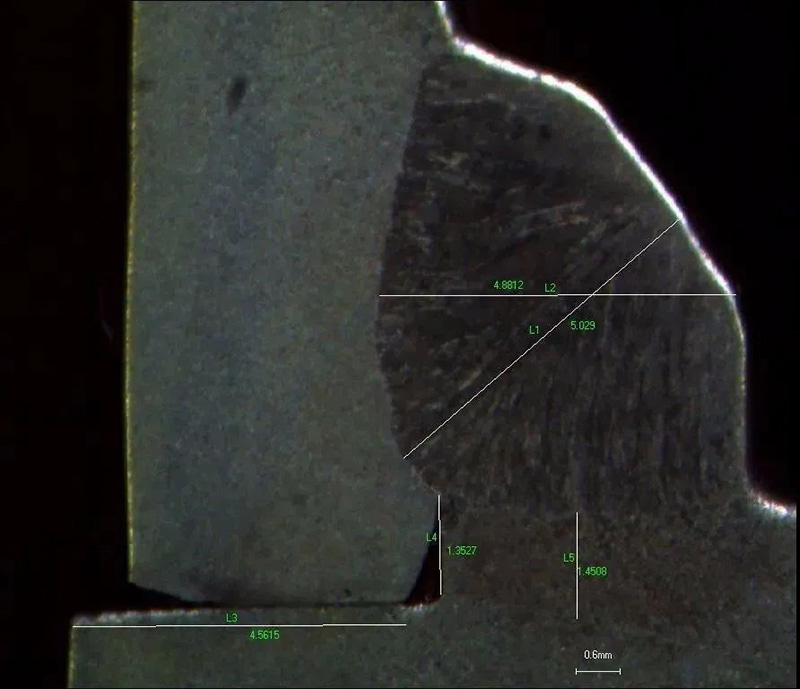

(1.2) Idatha yokungena yokushisela (onobude bomlenze obubonisa ukungena)

| U-L (mm) ubude bonyawo | |

| Ubude bonyawo | Idatha yokungena |

| L≤8 | Ngaphezulu kuka-0.2 * L |

| L>8 | ngaphezu kwe-1.5 mm |

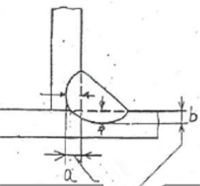

(2) Isilinganiso sokungena kokushisela (ibanga elingu-a no-b wukungena kokushisela)

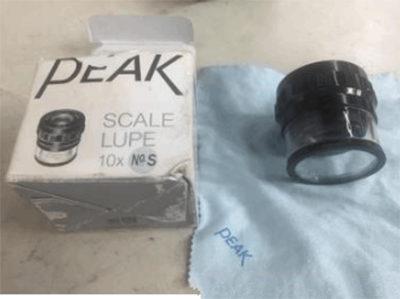

(3) Amathuluzi okuhlola okungena kwe-welding

Isinyathelo sesi-5: Umbiko wokuhlolwa wokungena kwe-welding nokugcinwa kwamasampula

(1) Umbiko wokuhlola ukungena kokushisela:

a.Ukwengezwa komdwebo wesigaba esiphambanayo sengxenye ehloliwe

b.Maka indawo yokulinganisa yokungena kwe-welding emdwebeni

c.Ukwengezwa kwedatha

(2) Imithethonqubo yokulondolozwa kwamasampula okungena kokushisela:

a.Ukugcinwa kwezingxenye zohlaka S iminyaka engu-13

b.Izingxenye ezijwayelekile zizogcinwa iminyaka emi-3

c.Uma kuchazwe ngenye indlela emdwebeni, kuzosetshenziswa ngokuvumelana nezidingo zomdwebo

(Indawo yokuhlola ukungena ingabhajwa ngokunamathela obala ukuze kubambezeleke ukugqwala)

Isikhathi sokuthumela: Dec-22-2022