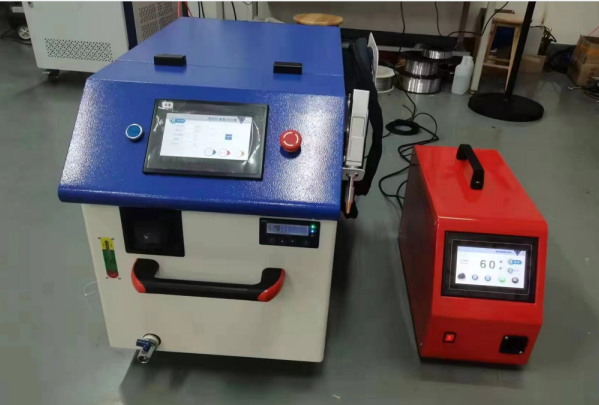

Abakhiqizi abangochwepheshe bomshini wokushisela we-laser obanjwa ngesandla isikhathi eside of umshini wokushisela we-laser ophethwe ngesandla, umshini wokusika i-laser bracket, umshini wokusika amapayipi we-laser nezinye izinhlobo zemishini yokusika i-laser kanye nemishini yokushisela i-laser welding, izinhlobo ezicebile, amamodeli aphelele, qiniseka ngemuva kokudayiswa.Inhlanganisela elandelayo yeminyaka yokuhlangenwe nakho kwakho ukuze ulungise izindlela ezisebenzayo kakhulu zokugcinwa komshini wokushisela we-laser.

1. Ukutholwa okuvamile: Ngemva kokusetshenziswa komshini ophathwa ngesandla we-laser welding, kufanele kubonwe njalo, njengokuthi ingabe ukujikeleza kwefeni okupholisa kuhamba kahle yini, noma kukhona ukudlidliza okungavamile nomsindo, noma kukhona ukuvuza kwegesi, amajoyinti ezintambo zokushisela. kanye nokuqhuma kosizo lwezempi kungakhathaliseki ukuthi kukhona ukuxebuka noma ukuxega, ikhebula linenkinga yokushisa engavamile, zonke izinto zokuhlola zitholwe zingajwayelekile, yima ngokushesha, lungiswa.

I-2, ukuhlanza uthuli okuvamile: umshini we-laser welding ophethwe ngesandla uphoqeleka ukupholisa umoya, kulula ukuhogela uthuli oluvela endaweni ezungezile, ngakho-ke kufanele senze ukuhlola okuvamile futhi sihlanze uthuli ngaphakathi komshini wokushisela.Ikakhulukazi i-transformer, i-reactance coil kanye negebe phakathi kwamalunga ekhoyili kufanele banake ngokukhethekile ukuhlanza.

I-3, hlola isikhundla se-wiring njalo: ukusatshalaliswa kwamandla ohlangothini lwamandla, amatheminali aseceleni okukhiphayo, kanye nendawo yokufaka izintambo zangaphakathi nezangaphandle, ingxenye ngayinye yesikulufu se-wiring ixega kufanele ihlolwe njalo, uma ukuhlolwa kuthola izingxenye zokugqwala susa ukugqwala ukuze wenze ukuthintana kube okuqhubayo.

I-4, enye iwukuhlolwa konyaka kanye nokugcinwa komshini wokushisela i-laser ophathwa ngesandla: Ukushisela ukusetshenziswa kwesikhathi eside kokusebenza, ngezinye izikhathi igobolondo ngenxa yokuguqulwa kokuxhumana, noma ukugqwala okumanzi, futhi izingxenye zangaphakathi nomsebenzi zizobulala, ngakho-ke ekugcinweni konyaka. kanye nokuhlolwa ukuze kusetshenziswe ukushintshwa kwezingxenye ezinesici kanye nokulungiswa kwamagobolondo kanye nezingxenye zokuwohloka kwezingxenye zokuqinisa kanye nomunye umsebenzi wokulungisa ophelele, izingxenye ezinesici zinconywa ukuba zithathe indawo yonke imikhiqizo emisha, ukuze kuqinisekiswe ukusebenza okuphelele kwe-welder.

Ukugcinwa okuvamile okungenhla kanye nokuhlolwa kwe-umshini wokushisela we-laser ophethwe ngesandlakufanele sinake, okunganciphisa kakhulu ukwenzeka kokuhluleka kwe-welding, kodwa futhi kwandise impilo yesevisi yomshini wokushisela kanye nokusebenza kahle komshini wokushisela, kodwa futhi kuthuthukise ukuphepha kokusebenza, ngakho-ke isixhumi se-laser esiphathwayo kufanele sikhokhe. ukunaka ukunakekelwa okujwayelekile kanye nokulungiswa kabusha, Okwengeziwe mayelana nomshini wokushisela we-laser kanye nezindlela zokugcinwa kwemishini ehlobene, siyakwamukela kuwebhusayithi yethu esemthethweni ukuze uqonde!

Isikhathi sokuthumela: Mar-07-2023