Isistimu yokulungisa ye-Laser Brazing

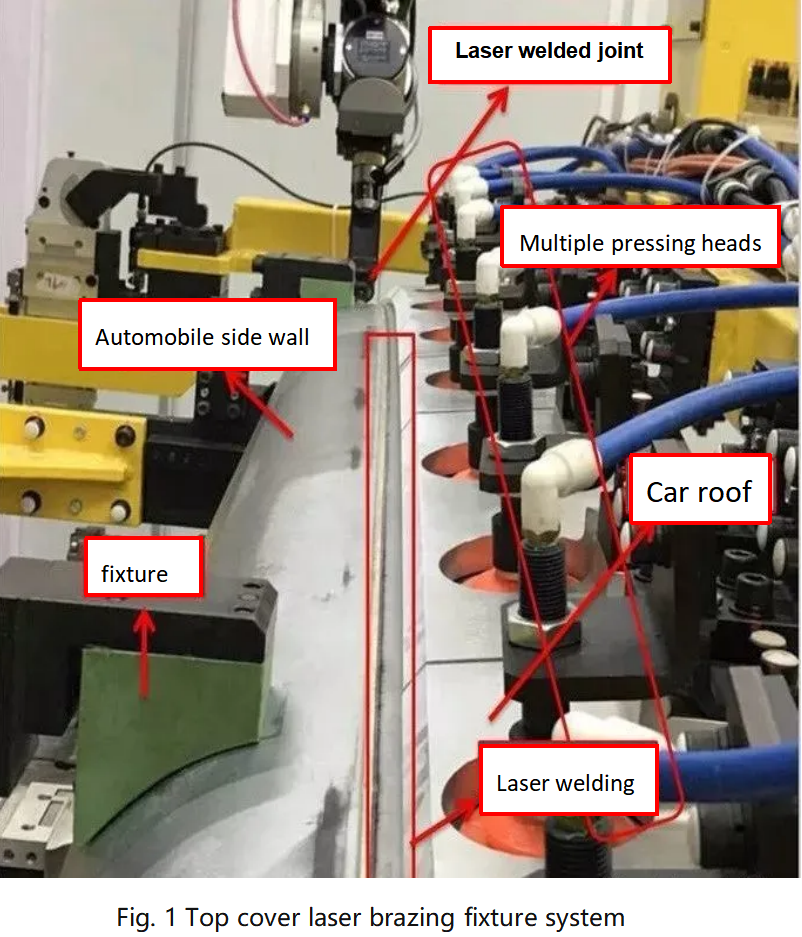

Ngesikhathi sokushiswa kwe-laser, kuyadingeka ukubamba ipuleti lensimbi elishiselwe ngokuqinile ngokwanele, ngakho-ke kuzoklanywa izinsimbi ezikhethekile.I-laser welding fixture inomthamo omkhulu kanye nesakhiwo esiyinkimbinkimbi.Isakhiwo sohlaka sisonke.Izinhlangothi ezingakwesokunxele nezingakwesokudla zomzimba wemoto zisekelwa amabhulokhi ezinto futhi ziboshwe ngamasilinda ngemva kokuma nokusekelwa.Ingxenye engenhla yakhelwe ngokubeka okukhethekile kanye nokubamba ngokucindezela kwe-laser brazing ophahleni lwemoto, ecindezelwa ngamakhanda amaningi okucindezela.Irobhothi libamba uphahla, lilubeke emzimbeni, bese lilubopha ngesilinda, ukuze amaphethelo epuleti lomzimba elizoshiselwa lilingane ngokwanele.Njengoba kuboniswe kuMfanekiso 1.

Izici zenqubo

• · Izinga lokushisa

• · I-angle yesigameko se-laser beam

• · Ukuhlanganisa nokususa ukugxila

• · Ukujula kokungena kokushisela

• · Umphumela wejubane lokushisela emandleni we-laser welding

Hlola

• 、 Ukuhlola okubonwayo

• Ngokusho kwe-German standard PV 6917 (ingatholakala ngokuthintana nombhali);

• Ukuhlolwa okubonwayo kuyokwenziwa ekuhlanganiseni ngakunye okungaxhunyiwe ku-inthanethi;

• Gxila ekutholeni ukungena kwe-weld (njengokungena okungaphelele, ukungena phakathi nokushiswa), futhi ucabangele isimo sendawo yokushisela (njenge-spatter kanye ne-porosity);

Indlela yokuhlola yokuhlola okubonwayo kwe-laser brazing ikhonjiswe kuThebula 1.

| Ithebula 1 Ukuhlolwa Kwekhwalithi Yokubukeka Kwe-Laser Brazing | ||

| Inombolo yomkhiqizo | Incazelo yesici | Ukuhlola iphutha |

| 1 | Izimbotshana eziveziwe | Uma izimo zivuma, indawo engaphezulu ingalungiswa inqobo nje uma ingathinti umsebenzi;Izimbobo zomoya ezinobubanzi obukhulu kuno-0.2mm kufanele zilungiswe |

| 2 | Ukuchichima kwe-Solder (kakhulu) | Uma izimo zivuma, indawo engaphezulu ingalungiswa inqobo nje uma ingathinti umsebenzi;Ingalungiswa |

| 3 | I-Ripple yesendlalelo endaweni ye-weld | I-joint kumele igcwaliswe nge-solder ngokuqhubekayo;Ingalungiswa |

| 4 | Ukuqhekeka kobuso (okuphambene nobude) kwenzeka endaweni yokushisela | Uma izimo zivuma, indawo engaphezulu ingalungiswa inqobo nje uma ingathinti umsebenzi;Ingalungiswa |

| 5 | Ukuqhekeka kobuso (okuphambene nobude) kwenzeka esisekelweni sensimbi | Ayifanelekile, edinga ukulungiswa |

| 6 | Ukungena kwensimbi okuyisisekelo | Ayifanelekile, edinga ukulungiswa |

| 7 | Ukungena ngaphansi nokungaphelele | Ayifanelekile, edinga ukulungiswa |

| 8 | isiphalaphala | Uma izimo zivuma, indawo engaphezulu ingalungiswa inqobo nje uma ingathinti umsebenzi;Ingalungiswa |

| 9 | Abangenanyama | Akuvunyelwe, ukulungiswa kuyadingeka |

| 10 | Indawo yokuqala ayishiselwe, futhi itheminali iboshwe | Akuvunyelwe, ukulungiswa kuyadingeka |

| 11 | I-Weld ayikho (igebe elikhulu lokufanisa) | Akuvunyelwe, ukulungiswa kuyadingeka |

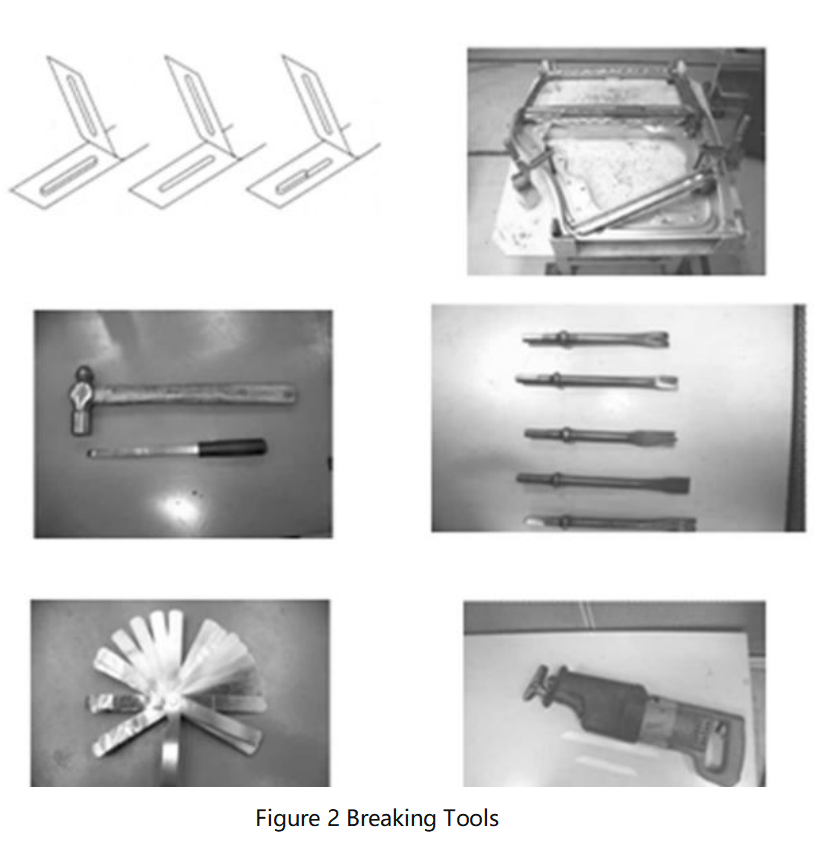

2 、 Ukuhlola okulimazayo

Amathuluzi okuhlola alimazayo aboniswa kuMfanekiso 2:

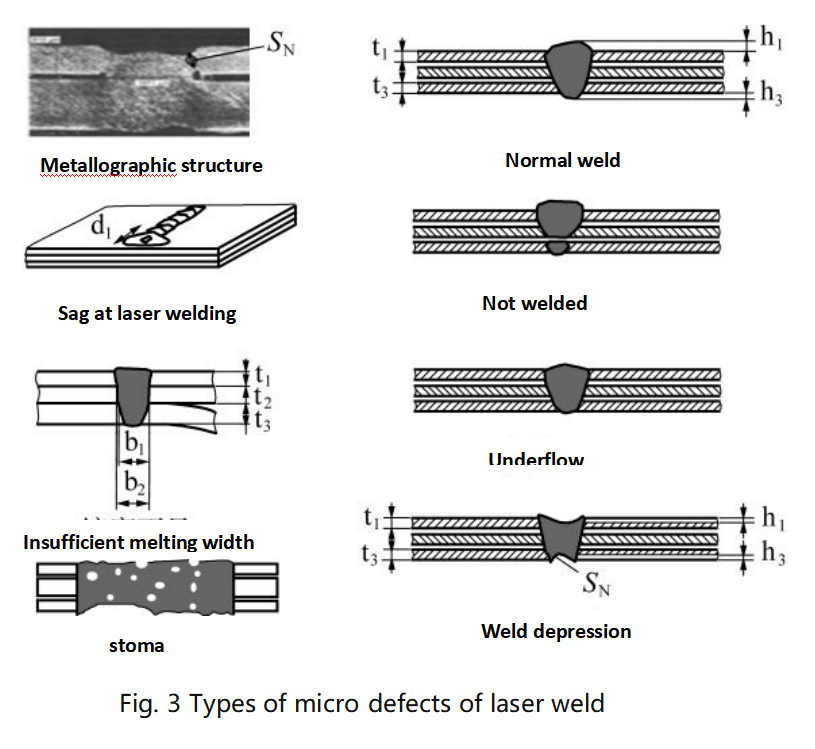

3, Ukuhlaziywa kwe-Metallographic Microscopic

Izinhlobo zokukhubazeka okuncane kwe-laser weld ziboniswa kuMfanekiso 3:

4, NDT

I-Ultrasonic, i-X-ray nezinye izinsimbi zingasetshenziswa ukuhlola ikhwalithi yokushisela i-laser.

Isifinyezo

Ngokusho komphumela wangempela wesicelo sobuchwepheshe be-laser welding ezitshalweni zezimoto, kungabonakala ukuthi ukushiswa kwe-laser akukwazi nje ukunciphisa isisindo somzimba wemoto, ukuthuthukisa ukunemba komhlangano womzimba wemoto, kodwa futhi kuthuthukisa kakhulu amandla emoto. umzimba, ihlinzeka abasebenzisi ngokuvikeleka okungcono ngenkathi bejabulela ukunethezeka.Kukholakala ukuthi ngokuthuthuka okuqhubekayo kwezinkinga zobuchwepheshe be-laser welding kanye nokwenza ngcono okuqhubekayo kwenqubo yokukhiqiza, i-laser welding izoba yingxenye ebalulekile yomzimba wemoto wesikhathi esizayo enqubweni yokukhiqiza emhlophe.

Isikhathi sokuthumela: Jan-09-2023