Njengoba sonke sazi, opharetha, abakhiqizi bemishini, abakhiqizi bemishini nabakhiqizi bezinto ezibonakalayo bakhe uchungechunge lwemboni yokuxhumana emise okwephiramidi ndawonye.Embonini, ubuchwepheshe bokupakisha bedivayisi yokuxhumana okubonakalayo ngokuvamile busebenzisa iglue ye-UV ukuze ibophe futhi ilungise idivayisi endaweni yokuhlangana.Okokuqala, i-glue ye-UV isetshenziselwa ukuhlangana kwedivayisi, bese isibani se-UV sisetshenziselwa ukukhanyisa nokuqinisa idivayisi.Le modi yokuxhumeka kwedivayisi inokukhubazeka okuningi, njengokujula okukhawulelwe kokupholisa;I-laser welding, uhlobo olusha lobuchwepheshe bokushisela, inezinzuzo zokushisela okuqinile, ukuguqulwa okuncane, ukunemba okuphezulu, isivinini esisheshayo nokulawula okuzenzakalelayo okulula, okwenza kube enye yezindlela ezibalulekile zobuchwepheshe bokupakisha idivayisi yokuxhumana optical.Okulandelayo kuchaza ubuchwepheshe bomshini wokushisela we-laser embonini yokuxhumana ye-optical.

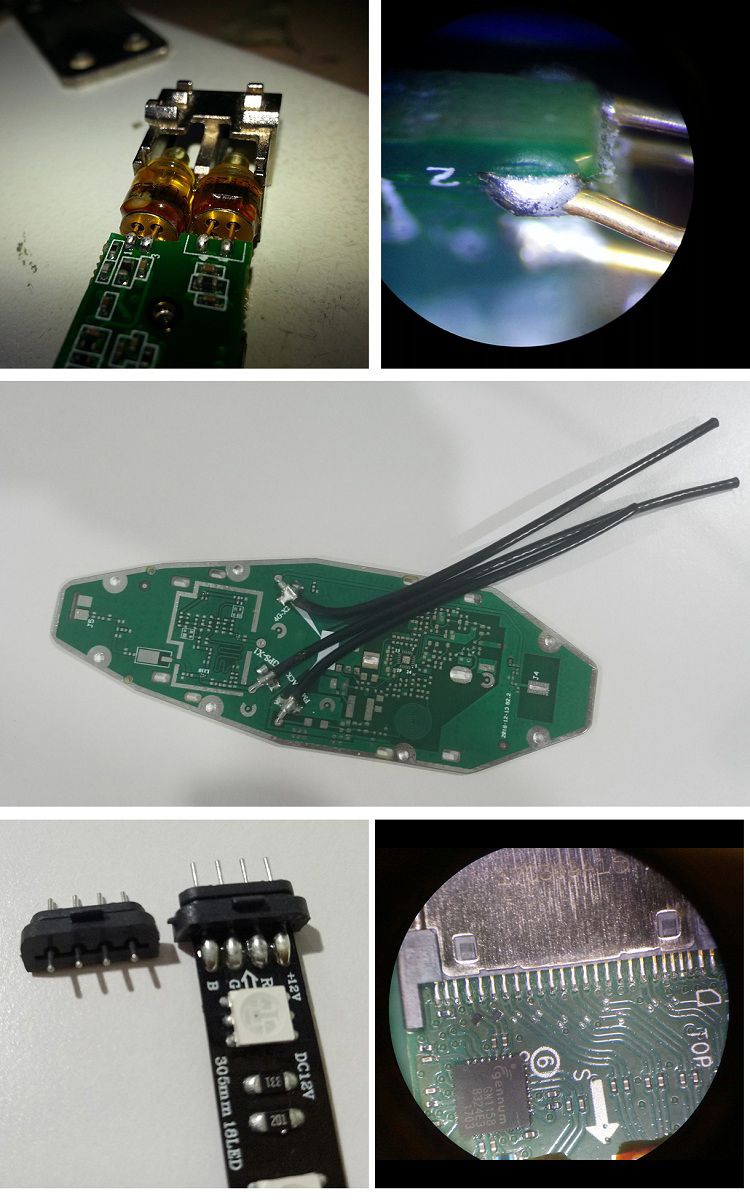

Imishini yokubona kanye namamojula optical atholakala phezulu nomfula wemishini yokuxhumana ye-optical.Umsebenzi oyinhloko wemojula ye-optical ukubona ukuguqulwa kwe-photoelectric.Njengoba i-chip ingumkhiqizo one-coefficient yobunzima obukhulu kunawo wonke ochungechungeni lwemboni ye-optical module, ngemuva kokuthi i-chip engenalutho kanye nebhodi lokufaka izintambo lifinyelele ukuxhumana okuncane, lidinga ukuvalwa epulasitiki, ingilazi, igobolondo lensimbi noma le-ceramic ngokusebenzisa ubuchwepheshe bokupakisha ukuze kuqinisekiswe ukuthi i-semiconductor edidiyelwe ye-circuit chip isebenza ngokujwayelekile ngaphansi kwezimo ezingezinhle ezahlukahlukene.I-laser welding isetshenziswa kakhulu kule nqubo.

Njengekhwalithi ephezulu, ukunemba okuphezulu, ukusebenza kahle okuphezulu kanye nendlela yokushisela isivinini, i-laser welding ibilokhu ikhathazeka futhi isetshenziswa.Ngenxa yobuningi bamandla e-laser, ukushisela nge-laser kuyashesha, kujulile futhi kuncane endaweni ethinteke ekushiseni, ekwazi ukubona ukushisela okuzenzakalelayo okunembayo.

Ngezidingo ze-miniaturization, ukusebenza okuphezulu, ukusebenza okuningi kanye nezindleko eziphansi zemishini kagesi, ubuchwepheshe be-laser welding, obunobuhle bokushisela okuqinile, ukuguqulwa okuncane, ukunemba okuphezulu, isivinini esisheshayo kanye nokulawula okuzenzakalelayo okulula ukukubona. enye yezindlela ezibalulekile zobuchwepheshe bokupakisha bedivayisi yokuxhumana.Ukusetshenziswa kwayo enqubweni yokukhiqiza yamadivayisi we-optoelectronic okuxhumana, izingxenye namamojula kungathuthukisa ngempumelelo ukunemba kwe-welding kanye nekhwalithi yokushisela.

Isikhathi sokuthumela: Dec-05-2022