Ukwelashwa kwe-Laser surface ubuchwepheshe obusebenzisa i-laser enamandla amakhulu ukushisisa indawo ebonakalayo ngendlela engathinteki, futhi ibona ukuguqulwa kwayo kwendawo ngokusebenzisa ukupholisa okupholisayo kwendawo ebonakalayo ngokwayo.Kuyazuzisa ukuthuthukisa izakhiwo zemishini nezomzimba zendawo yezinto ezibonakalayo, kanye nokumelana nokugqoka, ukumelana nokugqwala nokumelana nokukhathala kwezingxenye.Eminyakeni yakamuva, ubuchwepheshe bokwelashwa kwe-laser obufana nokuhlanza i-laser, ukucisha i-laser, i-laser alloying, ukuqinisa ukushaqeka kwe-laser kanye ne-laser annealing, kanye ne-laser cladding, ukuphrinta kwe-laser 3D, i-laser electroplating nobunye ubuchwepheshe bokukhiqiza i-laser additive buye baletha amathemba abanzi okusebenza. .

1. Ukuhlanza i-laser

Ukuhlanza i-laser kuwubuchwepheshe obusha obukhula ngokushesha bokuhlanza indawo, obusebenzisa ugongolo lwe-laser olunamandla amakhulu ukukhanyisela indawo yokusebenza, ukuze ukungcola, izinhlayiya noma ukunamathela okungaphezulu kuhwamuke noma kunwebeke khona manjalo, ngaleyo ndlela kufezwe inqubo yokuhlanza. kanye nokuhlanzwa.Ukuhlanza i-laser kuhlukaniswe ngokuyinhloko ekususeni ukugqwala, ukususwa kwamafutha, ukukhishwa kwepende, ukukhishwa kwe-coating kanye nezinye izinqubo;Ngokuyinhloko isetshenziselwa ukuhlanza insimbi, ukuhlanza izinsalela zamasiko, ukuhlanza izakhiwo, njll Ngokusekelwe emisebenzini yayo ephelele, ukucubungula okunembile nokuguquguqukayo, ukusebenza kahle okuphezulu nokonga amandla, ukuvikelwa kwemvelo okuluhlaza, akukho monakalo ku-substrate, ukuhlakanipha, ikhwalithi enhle yokuhlanza, ukuphepha, ukusetshenziswa okubanzi nezinye izici nezinzuzo, sekuye kwanda kakhulu emikhakheni ehlukahlukene yezimboni.

Uma kuqhathaniswa nezindlela zokuhlanza zendabuko ezinjengokuhlanza ukungqubuzana kwemishini, ukuhlanza ukugqwala kwamakhemikhali, ukuhlanza okuqinile okuqinile okuwuketshezi, ukuhlanzwa kwe-ultrasonic imvamisa ephezulu, ukuhlanza nge-laser kunezinzuzo ezisobala.

2. Ukucima i-laser

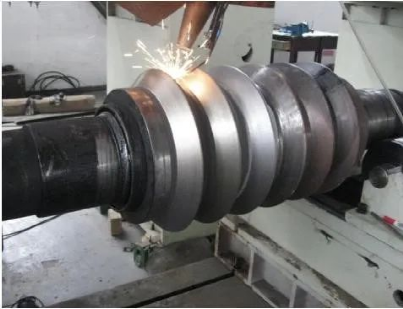

I-laser quenching isebenzisa i-laser enamandla amakhulu njengomthombo wokushisa ukwenza indawo yensimbi ishise futhi ibanda ngokushesha.Inqubo yokucisha iqedwa ngokushesha ukuze kutholwe ubulukhuni obuphezulu kanye nesakhiwo se-martensite se-ultra-fine, ukuthuthukisa ubulukhuni nokumelana nokugqoka kwendawo yensimbi, nokwenza ukucindezeleka okucindezelayo ebusweni ukuze kuthuthukiswe ukumelana nokukhathala.Izinzuzo eziyinhloko zale nqubo zihlanganisa indawo encane ethintekile ekushiseni, ukuwohloka okuncane, izinga eliphezulu lokuzenzakalela, ukuguquguquka okuhle kokucisha okukhethekile, ukuqina okuphezulu kwezinhlamvu ezicolisisiwe, nokuvikelwa kwemvelo okuhlakaniphile.Isibonelo, indawo ye-laser ingalungiswa ukuze icime noma yikuphi ukuma kobubanzi;Okwesibili, ikhanda le-laser kanye nokuxhumanisa irobhothi le-multi axis kungacisha indawo emisiwe yezingxenye eziyinkimbinkimbi.Kwesinye isibonelo, ukucisha i-laser kushisa kakhulu futhi kuyashesha, futhi ukucindezelwa okucishayo nokuguqulwa kuncane.Ukuguqulwa kwe-workpiece ngaphambi nangemva kokucisha i-laser kungacishe kunganakwa, ngakho-ke kulungele ngokukhethekile ukwelashwa okungaphezulu kwezingxenye ezinezidingo zokunemba okuphezulu.

Njengamanje, ukucinywa kwe-laser kusetshenziswe ngempumelelo ekuqinisweni kwezingxenye ezisengozini embonini yezimoto, embonini yesikhunta, amathuluzi e-hardware kanye nemboni yemishini, ikakhulukazi ekuthuthukiseni impilo yesevisi yezingxenye ezisengozini njengamagiya, izindawo ezingaphansi kwe-shaft, iziqondiso, imihlathi kanye nemishini. isikhunta.Izici ze-laser quenching zimi kanje:

(1) Ukucisha i-laser kuyinqubo yokupholisa esheshayo nejabulisayo, engadingi ukulondolozwa kokushisa kwesithando somlilo kanye nokucisha okupholisayo.Kuyinqubo yokwelapha ukushisa okungangcolisiwe, eluhlaza kanye nemvelo, futhi ingaqalisa kalula ukucisha iyunifomu ebusweni besikhunta esikhulu;

(2) Njengoba isivinini sokushisa kwe-laser sishesha, indawo ethintekile ekushiseni incane, futhi indawo yokushisa yokuskena engaphezulu iyacisha, okungukuthi, ukucisha ukushisa kwendawo ngokushesha, ukuwohloka kwefa eliphathwayo kuncane kakhulu;

(3) Ngenxa ye-engeli encane yokuhluka kwe-laser beam, inokuqondisa okuhle, futhi ingakwazi ukucisha ngokunembile indawo yesikhunta ngohlelo lomhlahlandlela wokukhanya;

(4) Ukujula kongqimba oluqinile lwe-laser surface quenching ngokuvamile kungu-0.3-1.5 mm.

3. Laser annealing

I-Laser annealing inqubo yokwelapha ukushisa esebenzisa i-laser ukushisa indawo ebonakalayo, ukuveza okokusebenza kumazinga okushisa aphezulu isikhathi eside, bese kupholile kancane.Inhloso eyinhloko yale nqubo ukukhulula ukucindezeleka, ukwandisa i-ductility yezinto ezibonakalayo kanye nokuqina, nokukhiqiza i-microstructure ekhethekile.Ibonakala ngokukwazi ukulungisa isakhiwo se-matrix, ukunciphisa ubulukhuni, ukucwenga okusanhlamvu nokuqeda ukucindezeleka kwangaphakathi.Eminyakeni yamuva, ubuchwepheshe be-laser annealing buye baba inqubo entsha embonini yokucubungula i-semiconductor, engathuthukisa kakhulu ukuhlanganiswa kwamasekethe ahlanganisiwe.

4. Ukuqinisa ukushaqeka kwe-laser

Ubuchwepheshe bokuqinisa ukushaqeka kwe-Laser ubuchwepheshe obusha futhi obuphakeme obusebenzisa i-plasma shock wave ekhiqizwe i-laser beam eqinile ukuze kuthuthukiswe ukukhathala, ukumelana nokugqoka kanye nokumelana nokugqwala kwezinto zensimbi.Inezinzuzo eziningi ezivelele, njengokuthi ayikho indawo ethintekile ekushiseni, ukusebenza kahle kwamandla okuphezulu, izinga lokucindezeleka okuphezulu kakhulu, ukulawuleka okuqinile nomthelela oqinisayo omangalisayo.Ngesikhathi esifanayo, ukuqinisa ukushaqeka kwe-laser kunezici zokucindezelwa okujulile kwensalela, i-microstructure engcono kanye nobuqotho bomhlaba, ukuzinza okungcono kokushisa nokuphila isikhathi eside.Eminyakeni yamuva, lobu buchwepheshe bufinyelele ukuthuthukiswa okusheshayo, futhi kunendima enkulu ku-aerospace, imboni yezokuvikela kazwelonke kanye nezempi kanye neminye imikhakha.Ngaphezu kwalokho, i-coating isetshenziselwa ikakhulukazi ukuvikela i-workpiece ekushiseni kwe-laser nokuthuthukisa ukumuncwa kwamandla e-laser.Njengamanje, izinto zokugqoka ezivame ukusetshenziswa upende omnyama kanye ne-aluminium foil.

I-Laser peening (LP), eyaziwa nangokuthi i-laser shock peening (LSP), iyinqubo esetshenziswa emkhakheni wobunjiniyela bomhlaba, okungukuthi, ukusetshenziswa kwemishayo ye-laser enamandla amakhulu ukuze kukhiqizwe izingcindezi eziyinsalela ezintweni zokuthuthukisa ukumelana nokuguga. (njengokumelana nokuguga nokumelana nokukhathala) kwezindawo ezibonakalayo, noma ukuthuthukisa amandla ezingxenye ezincane zezinto zokwakha ukuze kuthuthukiswe ubulukhuni obungaphezulu bezinto ezibonakalayo.

Ngokungafani nezinhlelo zokusebenza eziningi zokucubungula izinto, i-LSP ayisebenzisi amandla e-laser ekwelapheni ukushisa ukuze ifinyelele umphumela oyifunayo, kodwa isebenzisa umthelela we-beam ekucubungulweni kwemishini.I-laser yamandla aphezulu isetshenziswa ukuze ithinte indawo yokusebenza okuqondiswe kuyo ngamandla aphezulu i-pulse short.

I-beam yokukhanya ithinta ucezu lokusebenza lwensimbi, ihwamulise ucezu lokusebenza lube yisimo se-plasma emincane ngokushesha, futhi ifake ingcindezi ye-shock wave kucezu lokusebenza.Ngezinye izikhathi ungqimba oluncane lwempahla yokuvala i-opaque yengezwa endaweni yokusebenza ukuze kuthathelwe indawo ukuhwamuka kwensimbi.Ukucindezelwa, ezinye izinto zokumboza ezibonakalayo noma izendlalelo zokuphazanyiswa kwe-inertial zisetshenziselwa ukuthatha i-plasma (imvamisa amanzi).

I-Plasma ikhiqiza umphumela wokushaqeka kwamagagasi, ilolonge kabusha i-microstructure engaphezulu yendawo yokusebenza endaweni yomthelela, bese ikhiqiza ukusabela kochungechunge lokunwetshwa kwensimbi nokucindezelwa.Ukucindezeleka okujulile okucindezelayo okukhiqizwa yilokhu kusabela kunganweba impilo yengxenye.

5. Laser alloying

I-laser alloying ubuchwepheshe obusha bokuguqulwa kwendawo, obungasetshenziswa ukulungisa i-amorphous nanocrystalline eqinisiwe ye-cermet composite coatings phezu kwezingxenye zesakhiwo ngokuya ngezimo zesevisi ezihlukene zezinto zezindiza kanye nezici zokushisa kwe-laser ye-high density laser beam kanye nezinga lokufingqa, ukuze kuzuzwe inhloso yokuguqulwa kwendawo yezinto zezindiza.Uma kuqhathaniswa nobuchwepheshe be-laser alloying, ubuchwepheshe be-laser cladding bunezici zesilinganiso esincane sokuhlanjululwa kwe-substrate nechibi elincibilikisiwe, indawo encane ethintekile ekushiseni, ukuwohloka okuncane komshini wokusebenza kanye nezinga elincane le-scrap ye-workpiece ngemva kokwelashwa kwe-laser cladding.I-Laser cladding ingathuthukisa kakhulu izakhiwo ezingaphezulu zezinto, futhi ilungise izinto ezigugile.Inezici zokusebenza kahle okuphezulu, isivinini esisheshayo, ukuvikelwa kwemvelo okuluhlaza kanye nokungangcoli, kanye nokusebenza kahle kwe-workpiece ngemva kokwelashwa.

Ubuchwepheshe be-laser cladding bubuye bungobunye bobuchwepheshe obusha bokuguqula indawo emele isiqondiso sokuthuthukiswa kanye nezinga lobunjiniyela bangaphezulu.Ubuchwepheshe be-laser cladding sebuphenduke isizinda socwaningo ekuguqulweni komhlaba kwengxubevange ye-titanium ngenxa yezinzuzo zabo zokuhlanganisa okungangcolisi kanye ne-metallurgical phakathi kwe-coating ne-substrate.I-laser cladding ceramic coating noma i-ceramic ingxube eqinisiwe ye-ceramic iyindlela ephumelelayo yokuthuthukisa ukumelana nokugqoka okuphezulu kwe-titanium alloy.Ngokwezimo zangempela zokusebenza, khetha uhlelo olufanele lwezinto ezibonakalayo, futhi ubuchwepheshe be-laser cladding bungafinyelela izidingo zenqubo engcono kakhulu.Ubuchwepheshe be-laser cladding bungalungisa izingxenye ezihlukahlukene ezihlulekile, njengama-aeroengine blades.

Umehluko phakathi kwe-laser surface alloying kanye ne-laser surface cladding ukuthi i-laser surface alloying iwukuxuba ngokugcwele izakhi zengxubevange ezingeziwe kanye nongqimba lwangaphezulu lwe-substrate esimweni soketshezi ukuze kwakhe ungqimba oluyingxubevange;I-Laser surface cladding iwukuncibilikisa konke okokumbozwa ngaphambili kanye nokuncibilikisa okuncane okungaphezulu kwe-substrate, ukuze ungqimba oluhlanganisiwe nezinto ezingaphansi kwe-substrate yakhe inhlanganisela ye-metallurgical futhi igcine ukwakheka kongqimba lokunamathisela kungashintshile.Ubuchwepheshe be-laser alloying kanye ne-laser cladding busetshenziselwa ikakhulukazi ukuthuthukisa ukumelana nokugqokwa kwendawo, ukumelana nokugqwala kanye nokumelana nokugreda kwama-alloys e-titanium.

Njengamanje, ubuchwepheshe be-laser cladding busetshenziswe kabanzi ekulungiseni nasekuguquleni izindawo zensimbi.Kodwa-ke, nakuba ukufakwa kwe-laser yendabuko kunezinzuzo nezici zokucutshungulwa okuguquguqukayo, ukulungiswa okumise okukhethekile, isithasiselo esichazwe ngumsebenzisi, njll., ukusebenza kahle kwayo kuphansi, futhi namanje akukwazi ukuhlangabezana nezidingo zokukhiqiza nokucubungula okukhulu ezinye izinkambu zokukhiqiza.Ukuze kuhlangatshezwane nezidingo zokukhiqiza ngobuningi futhi kuthuthukiswe ukusebenza kahle kokumboza, kwavela ubuchwepheshe be-laser cladding enesivinini esikhulu.

Ubuchwepheshe be-laser cladding obunesivinini esiphezulu bungabona isendlalelo samahhala sokuvala esihlangene nesinesici.Izinga eliphezulu le-cladding layer ihlangene, i-metallurgical bonding ne-substrate, azikho iziphambeko ezivulekile, futhi ingaphezulu libushelelezi.Akukwazi ukucutshungulwa kuphela emzimbeni ojikelezayo, kodwa futhi endizeni kanye nendawo eyinkimbinkimbi.Ngokuqhubeka nokwenza kahle kwezobuchwepheshe, lobu buchwepheshe bungasetshenziswa kabanzi kumalahle, insimbi, amapulatifomu asogwini, ukwenza amaphepha, izinto zikagesi zomphakathi, izimoto, imikhumbi, uphethiloli, izimboni ze-aerospace, futhi kube inqubo yokukhiqiza kabusha eluhlaza engangena esikhundleni sobuchwepheshe bendabuko be-electroplating.

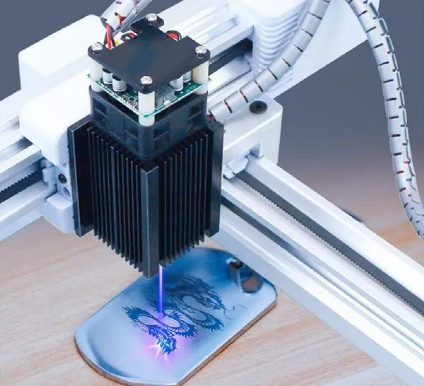

7. Ukuqoshwa kwe-laser

Ukuqoshwa kwe-laser kuyinqubo yokucubungula nge-laser esebenzisa ubuchwepheshe be-CNC ukuze kusetshenziswe ugongolo lwe-laser olunamandla amakhulu endaweni yezinto ezibonakalayo, futhi kusebenzisa umthelela oshisayo okhiqizwa i-laser ukukhiqiza amaphethini acacile endaweni ebonakalayo.I-denaturation ebonakalayo yokuncibilika kanye nokufakwa kwe-gasification kwezinto zokucubungula ngaphansi kokushiswa kwe-laser eqoshiwe kungavumela ukuqoshwa kwe-laser ukufeza izinjongo zokucubungula.Ukudweba nge-laser ukusebenzisa i-laser ukuze uqophe amagama entweni.Amagama aqoshwe yilobu buchwepheshe awanawo ama-nick, ingaphezulu lezinto libushelelezi futhi liyisicaba, futhi umbhalo wesandla ngeke ugqokwe.Izici zayo kanye nezinzuzo zihlanganisa: ephephile futhi enokwethenjelwa;Inembile futhi icophelela, ukunemba kungafinyelela ku-0.02mm;Londoloza ukuvikelwa kwemvelo kanye nezinto ngesikhathi sokucubungula;Isivinini esikhulu, ukuqoshwa kwesivinini esikhulu ngokusho kwemidwebo yokuphuma;Izindleko eziphansi, azikhawulelwe ngobuningi bokucubungula, njll.

8. Ukuphrinta kwe-Laser 3D

Inqubo isebenzisa ubuchwepheshe be-laser cladding, obusebenzisa i-laser ukuze buthuthe ukugeleza kwempushana ethuthwa ngombhobho ukuze kuncibilike ngokuqondile into elula noma i-alloy powder.Ngemva kokushiya i-laser beam, uketshezi lwe-alloy luqina ngokushesha ukuze kubonakale ukuboniswa okusheshayo kwe-alloy.Njengamanje, isetshenziswe kabanzi ekufaniseni izimboni, ukukhiqizwa kwemishini, i-aerospace, amasosha, izakhiwo, ifilimu nethelevishini, izinto zikagesi zasendlini, imboni yokukhanya, imithi, imivubukulo, isiko nobuciko, ukubaza, ubucwebe kanye neminye imikhakha.

9. Izicelo ezijwayelekile zezimboni zokwelashwa kwe-laser surface kanye nokwenza kabusha

Njengamanje, ukwelashwa kwe-laser surface kanye nobuchwepheshe bokukhiqiza okungeziwe, izinqubo kanye nemishini isetshenziswa kabanzi kwezensimbi, imishini yezimayini, isikhunta, amandla kaphethiloli, amathuluzi wehardware, ezokuthutha ngojantshi, i-aerospace, imishini nezinye izimboni.

10. Ukusetshenziswa kobuchwepheshe be-laser electroplating

I-Laser electroplating ubuchwepheshe obusha be-electroplating obunamandla amakhulu, obubaluleke kakhulu ekukhiqizeni nasekulungiseni amadivaysi e-microelectronic namasekhethi amakhulu ahlanganisiwe.Njengamanje, nakuba isimiso se-laser electroplating, i-laser ablation, i-plasma laser deposition kanye nejethi ye-laser kusengaphansi kocwaningo, ubuchwepheshe babo sebusetshenzisiwe.Lapho i-laser eqhubekayo noma i-pulse laser ikhanyisa indawo ye-cathode endaweni yokugeza ye-electroplating, akukhona nje kuphela ukuthi izinga lokubeka insimbi lingathuthukiswa kakhulu, kodwa futhi ikhompuyutha ingasetshenziswa ukulawula i-trajectory ye-laser beam ukuthola ukunamathela okungavimbelwe i-geometry eyinkimbinkimbi elindelekile.

Ukusetshenziswa kwe-laser electroplating ekusebenzeni kusekelwe ikakhulukazi kulezi zici ezimbili ezilandelayo:

(1) Ijubane endaweni yokukhipha imisebe ye-laser likhulu kakhulu kunejubane le-electroplating emzimbeni (cishe izikhathi eziyi-103);

(2) Ikhono lokulawula le-laser linamandla, elingenza ingxenye edingekayo yezinto ezibonakalayo isheshise inani elidingekayo lensimbi.I-electroplating evamile yenzeka kuyo yonke i-electrode substrate, futhi isivinini se-electroplating sihamba kancane, ngakho-ke kunzima ukwenza amaphethini ayinkimbinkimbi futhi amahle.I-Laser electroplating ingalungisa i-laser ibe usayizi we-micrometer, futhi ilandele umkhondo ongenakuvinjelwa ngosayizi we-micrometer.Ngomklamo wesekethe, ukulungiswa kwesekethe kanye nokubekwa kwendawo ezingxenyeni zesixhumi se-microelectronic, lolu hlobo lwemephu enesivinini esikhulu luya ngokuya lusebenza.

Uma kuqhathaniswa ne-electroplating evamile, izinzuzo zayo yilezi:

(1) Isivinini sokubeka ngokushesha, esifana ne-laser gold plating efika ku-1 μ M/s, i-laser yethusi ecwebezelayo efinyelela ku-10 μ M/s, i-laser jet gold plating efinyelela ku-12 μ M/s, i-laser jet copper epulate kufika ku-50 μ m/s;

(2) Ukufakwa kwensimbi kwenzeka kuphela endaweni ye-laser irradiation, futhi ukumbozwa kwendawo kungatholakala ngaphandle kwezinyathelo zokuvikela, ngaleyo ndlela kube lula inqubo yokukhiqiza;

(3) I-adhesion enamathela ithuthukiswa kakhulu;

(4) Kulula ukubona ukulawula okuzenzakalelayo;

(5) Londoloza izinsimbi eziyigugu;

(6) Londoloza utshalomali lwemishini nesikhathi sokucubungula.

Lapho i-laser eqhubekayo noma i-laser impulse ikhanyisa indawo ye-cathode endaweni yokugeza ye-electroplating, akukhona nje kuphela ukuthi izinga lokubeka insimbi lingathuthukiswa kakhulu, kodwa futhi ikhompuyutha ingakwazi ukulawula ithrekhi yokunyakaza kwe-laser beam ukuze ithole ukumbozwa okungavimbelwe nge-complex elindelekile. ijiyomethri.Ubuchwepheshe obusha bamanje be-laser jet i-electroplating ethuthukisiwe buhlanganisa ubuchwepheshe be-electroplating obuthuthukisiwe ne-electroplating solution yokufafaza, ukuze i-laser nesisombululo sokucwenga kukwazi ukudubula ngesikhathi esisodwa endaweni ye-cathode, futhi isivinini sokudlulisa ngobuningi sishesha kakhulu kunesivinini sokudlulisa ngobuningi. ukushukuma okuncane okubangelwa ukukhanya kwe-laser, ngaleyo ndlela kufinyelele isivinini esikhulu sokubeka.

Ukuthuthukiswa kwekusasa kanye nokuqanjwa kabusha

Ngokuzayo, isiqondiso sokuthuthukiswa kokwelashwa kwe-laser surface kanye nemishini yokukhiqiza eyengeziwe ingafingqwa ngale ndlela elandelayo:

· Ukusebenza kahle okuphezulu - ukusebenza kahle okuphezulu kokucubungula, ukuhlangabezana nesigqi sokukhiqiza esisheshayo semboni yesimanje;

·Ukusebenza okuphezulu - okokusebenza kunemisebenzi eyahlukene, ukusebenza okuzinzile futhi kufanele izimo zokusebenza ezehlukene;

·Ubuhlakani obuphezulu – izinga lobuhlakani lilokhu lithuthuka, kuncane ukungenelela okwenziwa ngesandla;

·Izindleko eziphansi – izindleko zemishini ziyalawuleka, futhi nezindleko zezinto ezisetshenziswayo ziyancishiswa;

·Ukwenza ngokwezifiso - ukwenza ngokwezifiso okomuntu siqu kwemishini, isevisi enembile yangemva kokuthengisa,

·Nokuhlanganiswa - ukuhlanganisa ubuchwepheshe be-laser nobuchwepheshe bokucubungula bendabuko.

Isikhathi sokuthumela: Sep-17-2022